CONSTRUCTION SITE EQUIPMENT

The company A.E.I. was founded in 1992 as an associate company of Fuhrmann Fahreuge GmbH.

The location of A.E.I. is in south Moravian Feldsberg / Valtice in the Czech Republic, the former headquarters of the Price of Liechtenstein, next to the border to Austria.

Feldsberg has a border station for passenger and car traffic to Schrattenberg / Austria, the goods traffic will be handled by the nearby, only 12 km away, international border crossing Drasenhofen / Mikulov.

Since 1994 company A.E.I. is working on the development, planing, designing and production of equipment for the construction industry.

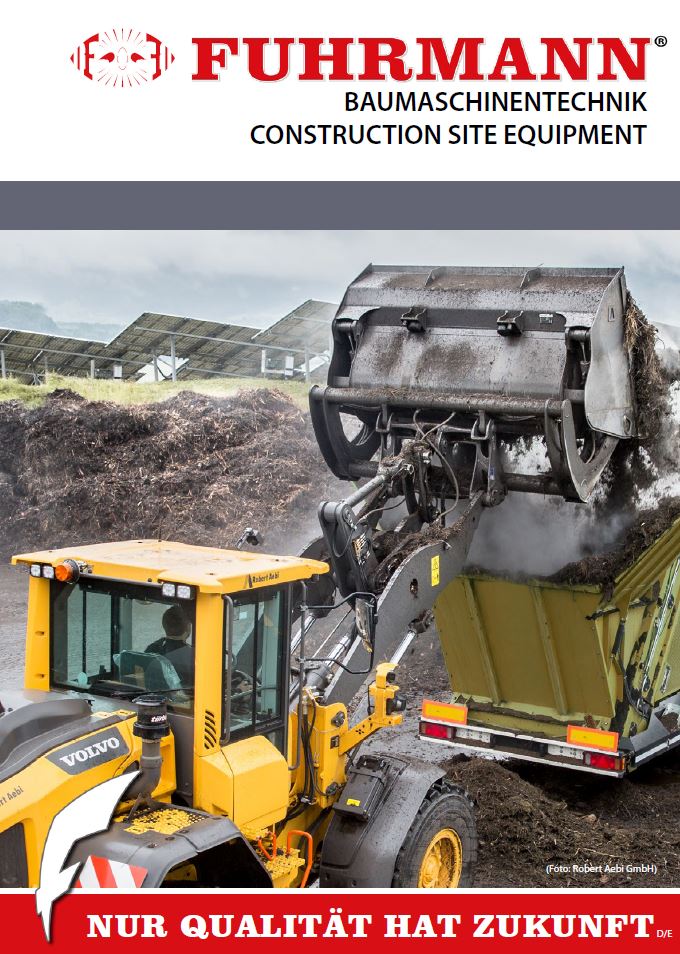

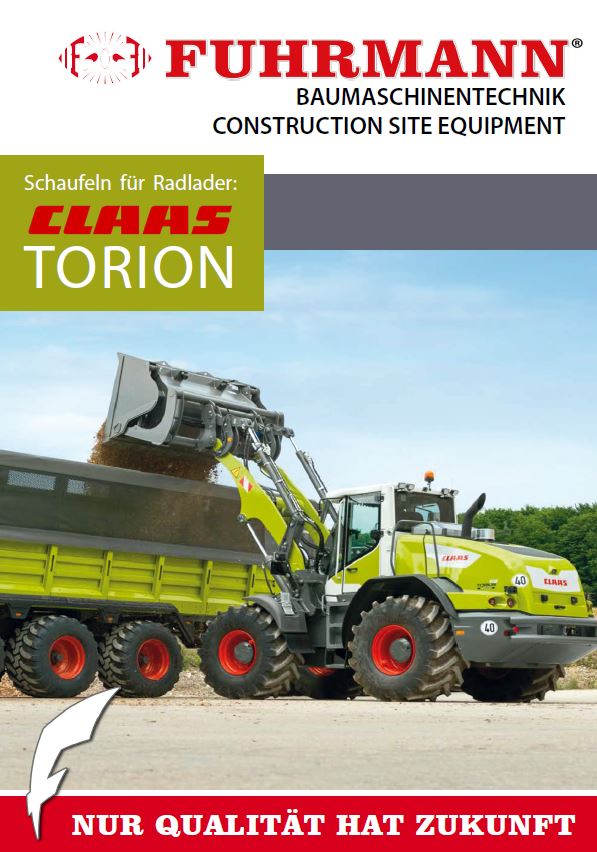

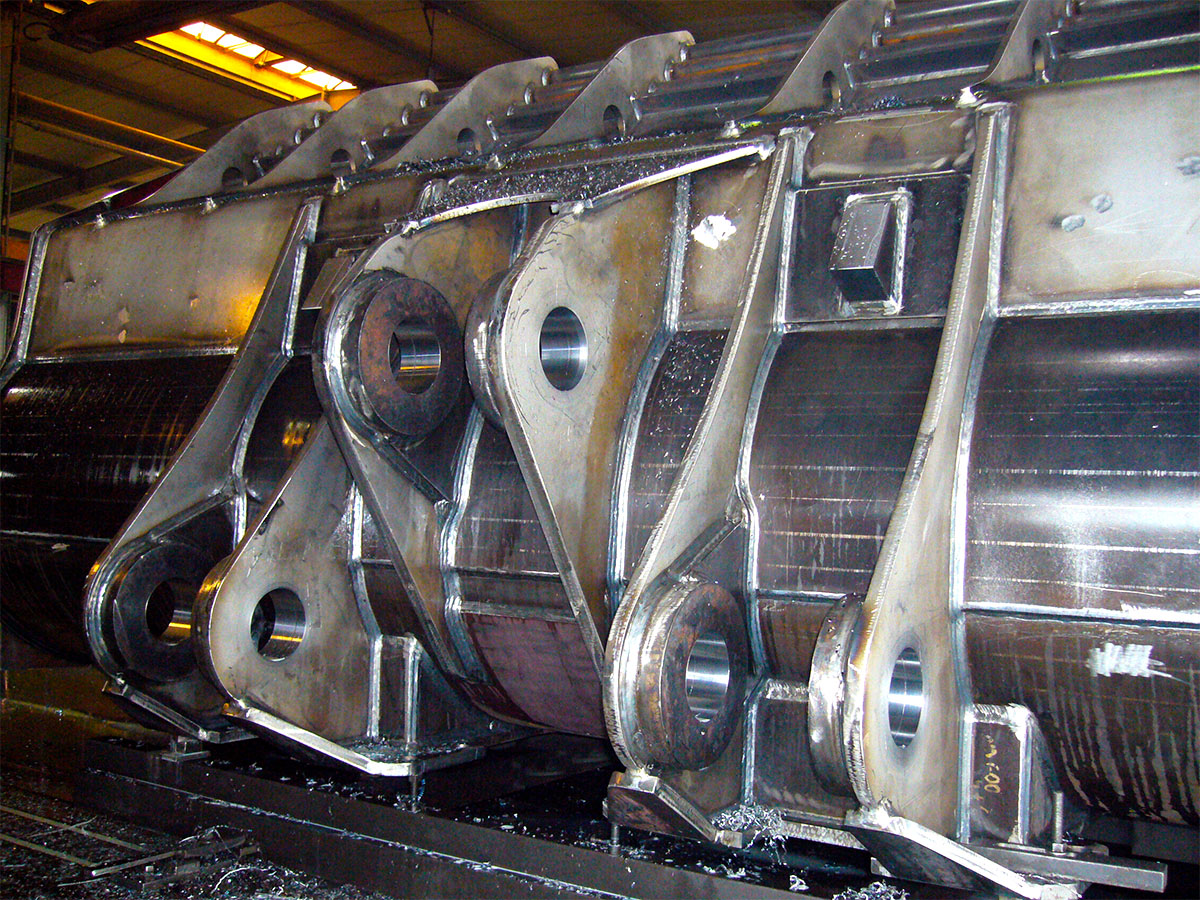

The core business consists of working with leading manufacturers of construction machinery industry. The product range includes a wide range of loader buckets in size from 0,5 to 18 m³ content, available in standard, heavy rock, light-material and high-tip design. We are able to develop and to produce exavator buckets, quick coupler systems and a wide range of customised special equipment.

|

|

|

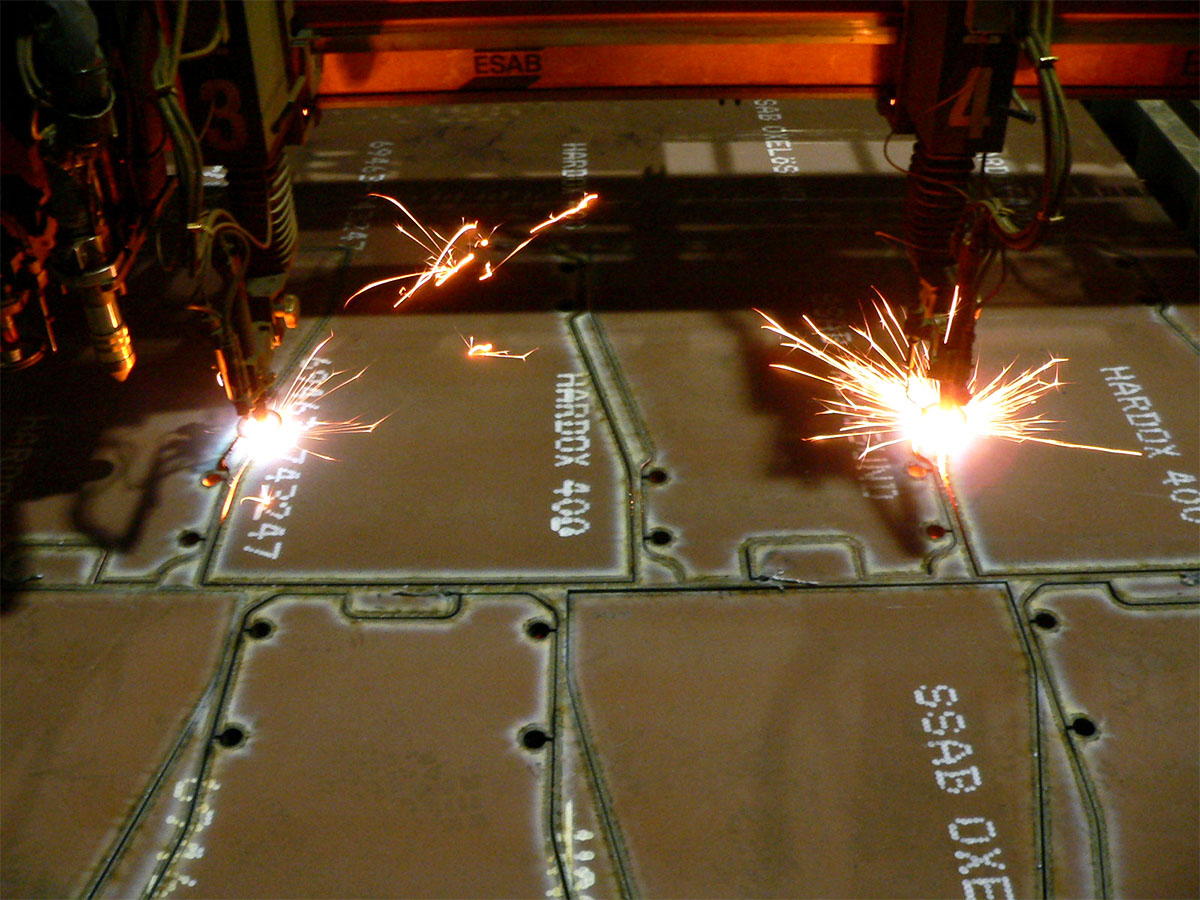

| The design department is using the latest CAD software, which enables us to implement customized solutions quickly and professionally. The cutting of our parts will be done on our CNC-cutting machine which is directly linked to our CAD-system. The high precision and capacity of the machine, on which metal sheets in sizes up to 12 x 3 m and thickness from 1 to 200 mm plasma or autogenously will be cut, ensures hight accuracy and short production time of the internal cutting orders. Normally we use steel plates in grades QSTE380TM and highly wear-resistant plates in grades HARDOX 400/500/600. |

|

|

|

|

Bending works will be done on a 1.000 ton / 7.5 m press brake. This machine allows us to bend plates in the quality Hardox 400 up to 25 mm.

The assembly and welding of the pars is carried out by qualified skilled workers. Assemblies and small parts up to a weight of 1000 kg are made in serial-production on our standard welding robot system.

The mechanical machining is performed on the

finished welded components can be machined up to size of 8 x 2,5 m and up to a weight of 40 tons in on setting.

The final inspection and acceptance of each internal component documenting the quality of our products and guarantee our customers the quality standards expected by them.

The sandblasting and painting of the components are connected to the production in the paint shop.

Our goal is using the available know-how and experience of our highly qualified staff to handle existing mechanical and local resources in the 1999 new built production plant optimally.

Certification is ISO 9001 and ISO 14001 shows way of thinking and specified rules in our company concerning the use of the term quality.